Sanitation vehicles are increasingly turning to lithium batteries, which are lighter, able to charge more quickly and have a longer life than traditional batteries. But they are also finicky to deal with, especially when it comes to storage. When stored improperly, they can overheat, short circuit or catch fire. That is why it’s important for those handling these vehicles to understand how to store these batteries properly. Whether your role involves managing a fleet or performing maintenance, taking a few simple precautions can help safeguard your employees, your equipment and your facility. Here’s a rundown of what you need to know to do it right.

Removing and Charging the Battery

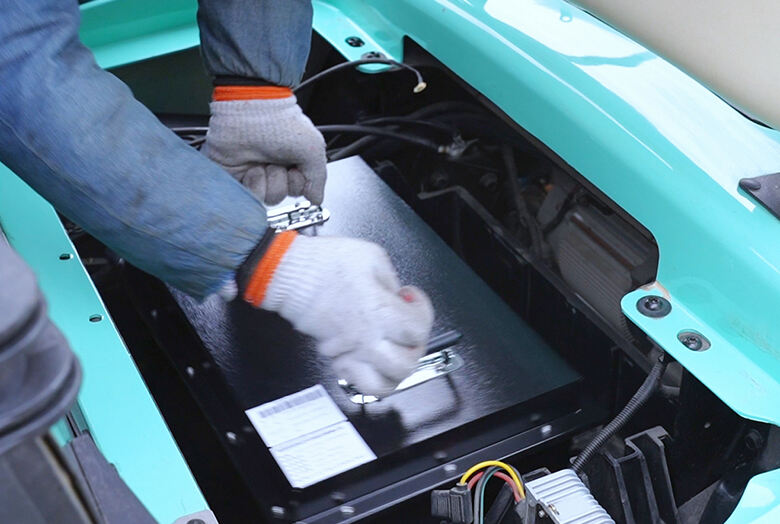

Before pulling or charging lithium battery from sanitation vehicle, please ensure that the vehicle is power off and keep on dry environment. Most vehicles come with a lock or disconnect switch for this purpose, and you should always use it. Unscrew the battery cables, being sure to begin with the negative (black) terminal disconnected. Put on gloves and safety glasses, just to be safe. Some batteries can be heavy, so if it’s a large pack, you may need a mechanism for lifting it or a second person to help.

When that is done, place the battery on a non-conductive surface such as a rubber mat or wooden bench. Never put it down on concrete or metal without insulation below the robot as this can be a short circuit or may shorten battery life. Now, inspect the battery for damage — warning signs include bulging, cracks or unusual odours. “Whatever, doesn’t matter,” Lamey says about bad battery “If something’s not good, you don’t charge it and you put it away in a safe location and you call a manned battery technician.

For charging, use the charger that the battery came with or one that is recommended by the battery manufacturer. An incompatible charger could cause the battery to overheat, or otherwise to be damaged. The charger should be plugged into a convenient power source which should be kept dry and out of sight of water. If you’re charging multiple batteries simultaneously, separate them so they don’t overheat.

There should always be charging in a well-ventilated place. Some facilities have theirs in separate charging rooms or cabinets for the purpose. A general rule of thumb is to not leave charging batteries unsupervised for extended periods of time. If your crew members charge overnight invest in chargers with automatic shut-off or a battery management system that can send alerts if anything goes wrong.

Taking care of batteries and charging them correctly can reduce the risk of damage and help you get the most out of them.

Finding the Right Storage Area

As critical as it is to handle lithium batteries safely, selecting the proper place to store them also matters. A properly picked storage location can avoid some accidents and prolong the battery life.

— Temperature, Light & Humidity

Begin by choosing a cool, dry location free from direct sunlight. That’s because heat is among a lithium battery’s worst enemies. They can become destabilized if stored in a hot room or next to machinery that emits heat. Keep the storage temperature of 15°C and 25°C (59°F- 77°F). Stay away from anywhere damp, or where water could get in — batteries and water are not friends.

A real-world example is playing out at a city garage in Ohio. After one of the near-miss episodes, a battery had swollen under inadequate ventilation, they improved their storage setup with better airflow and a temperature-monitoring system. Since then, there has been no other trouble. Small changes like these are making a big difference.

— Airflow

Storage should take place in a well-ventilated area. And if a battery does begin to overheat or emit gas, good airflow can limit the danger of fire. Do not leave batteries in closed cabinets or small rooms with no air circulation. Also, don’t store them near anything that ignites, such as oil, gas or cleaning fluids. These, in the event of any fire, would only make things worse fast.

— Physical Location

Always keep batteries on non-conductive shelves or counters, it can be both plastic or wooden. Any metallic shelf can be employed provided it stores batteries in plastic bins or on rubber mats, so that the batteries do not touch the shelf. Continue to store batteries off the floor in the event of a flood or leaks.

Clearly label the storage space, and limit access to trained personnel. It’s also wise to have a fire extinguisher close at hand that is rated for electrical fires (Class C or ABC). Some sanitation departments have installed thermal cameras specifically to monitor temperatures near stored batteries.

What is a lithium iron phosphate battery?

The lithium iron phosphate battery, also called LFP battery is a type of rechargeable battery, specifically a lithium-ion battery, which uses LiFePO₄as a cathode material, and a graphitic carbon electrode with a metallic backing as the anode. This type of battery is highly relevant for cleaning electric vehicles, which are e.g. floor scrubbers or sweepers. Comparing with the traditional lithium ion battery (Ternary lithium battery), the lithium iron phosphate battery has stronger structural stability and its fire or explosion is not easy to happen.

How do lithium-iron phosphate batteries work?

Lithium iron phosphate batteries exchange lithium ions between the graphite negative electrode and the iron phosphate positive electrode during discharging or charging. Its core advantages are:

Stable chemical property: iron phosphate is stable and not easy to decompose, avoiding oxygen loss and ensuring safety;

Strong Thermal Stability: No Fire No Explosion Under extreme Temperature From -20ºC-130ºC or Over Charge / Discharge;

BMS Directive Security: The built-in BMS manages voltage, current, and internal temperature in real time.

These batteries are well suited to electric clean equipment which need safety and long life.

Key applications of lithium iron phosphate battery

Real-world example: Some trash collection companies in Europe have converted their electric garbage trucks to LFP batteries for its safety and endurance. Following tests in summer heat and winter cold, the trucks proved to be reliable and required less maintenance than vehicles equipped with older battery technology.

—Sanitation vehicles

LiFePO4 batteries are in service in:

Floor scrubbers and sweepers (such as Mingnuo scrubbing machines) : 【For the entire vehicle】 Efficient, Durable, ENERGY;

Urban road and park sweepers: recharging and discharging are executed rapidly;

Industrial Site Cleaning Machines: to withstand constant use and despite in rugged working conditions.

The battery can defend shift operation, and decrease its maintenance cost and consumption.

Benefits of lithium iron phosphate battery

— BMS Battery Management System

Free and simple app to monitor your battery, LFP batteries are known for their safety Such cells pose more risk to safety. They are far less likely to overheat or catch fire than other lithium-ion batteries. That’s because lithium iron phosphate, the chemistry used by Mingnuo, has a more stable chemistry, even under extreme temperatures or heavy use. That makes them particularly well suited for the inside of sanitation vehicles, which are used in all kinds of weather and under variously tough conditions.

All lithium iron phosphate batteries of Mingnuo are assembled by intelligent BMS which has the following functions:

Over-charge / Over-discharge protection: never allow over-charging or discharging the battery, effectively extend the battery life.

Temperature control and alarm: real-time monitoring the temperature to prevent over-charging.

Over current protection (current overload protection): Prevent damage due to high current discharging.

The BMS is the battery’s ‘brain’ under load – optimizing power, extending run time, and life of the battery, and protecting the battery system from over pattering, overcharging and overheating.

— Deep Waterproofing Design

Mingnuo battery modules are IPX-rated for watery, and humid, even for direct washdown:

Fully sealed construction: prevent water vapor entering in the battery, and protect battery cells;

Apply to integration washing/sweeping machine: Applicable to wet ground and outdoor work;

Housing: corrosion resistant housing to extend the life of the battery.

The deep sealing waterproof battery system is required to ensure the all-weather running of the cleaning machinery.

And they have a long life. LFP batteries can endure thousands of charge cycles before losing significant capacity. For instance, an LFP battery may last 2,000 to 5,000 cycles or more, while other lithium batteries may last only around 1,000 cycles. This translates to less equipment replacement and downtime.

If you are involved with battery-operated sanitation trucks, whether working in real-world operations or reaffirming that the referenced LFP type of battery system exists, having a general awareness of the battery can help you make informed decisions on storage, charging and long-term care.

Building a Proper Battery Management System

A BMS or Battery Management System they are the brain of your lithium battery system. It monitors the health of each battery to ensure that everything is operating safely and efficiently. For utility trucks, which makes a lot of starts, stops and is engaged in heavy lifting, a robust BMS is essential. It works against overcharging, deep discharging, over heating, and short circuit problem which can do a great harm to your battery or create a dangerous incident.

Begin with selecting a BMS that compatible with your battery type. If you’re utilizing lithium iron phosphate (LFP) batteries, design your system for LFP. A proper BMS monitors every individual cell inside the battery pack. It equalizes the charge so that no one cell becomes overly full or empty. When your apps draw more power than this balance allows, your battery can degrade faster or become unable to function properly.

One tip is: try to get a BMS that is user friendly. A few systems enable you to also view real-time data from a phone or a computer. Things like temperature, charge and voltage can be checked. This is helpful in the early identification of problems. If a battery is getting hot, or running down very quickly, the BMS will let you know (Picture: BMS dashboard on a tablet).

Remote monitoring is particularly valuable for sanitation fleets. Maintenance crews can monitor a fleet of vehicles and schedule service in advance of problems. In one city in Arizona, a maintenance team has a central dashboard that signals when a battery’s charge falls below a safe level. This enabled them to nab a bad battery before it failed on a route, saving time and preventing any disruptions in trash pickup.

Also, have safety cutoffs for the BMS. If something goes wrong, such as a sudden spike in voltage, the system will shut down charging or discharging to prevent damage. It’s not just about protecting the battery; it’s about protecting people, too.

The bottom line is, a good BMS makes it no guesswork for battery caring. It helps keep your garbage trucks operating safely, improves the longevity of your batteries and can help prevent repair expenses over the long-term.

Mingnuo offers lithium batteries for sanitation vehicles.

Mingnuo: Manufacturer of electric sanitation vehicles and lithium battery solution The Mingnuo! Their lithium-ion batteries are light, and have a long cycle life and a high energy density, and are ideal for a range of electric vehicles such as garbage trucks and road sweepers. Such devices will lead to cleaner and quieter urban living, as these batteries replace environmentally unfriendly engines.

Mingnuo produces electric garbage trucks, floor scrubbers, and road sweepers – all are running on Mingnuo’s lithium battery tech. For example, the MINGNUO H91 Electric Garbage Truck is capable of carrying up to 3.6 cubic meters and comes with a motor rated at 7500W, this makes waste collection much easier.

It concentrates on the environmental advantages, cost savings and functional efficacy of its products. With their longer lifespan, their lithium batteries also last longer than old-style lead acid ones, which means less maintenance and downtime savings.

Mingnuo is a game-changer in electric sanitation vehicles and the lithium battery industry with its continuing focus on innovation and sustainability.

EN

EN

AR

AR

BG

BG

HR

HR

NL

NL

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

HY

HY

KA

KA

BN

BN

BS

BS

MN

MN

KK

KK

UZ

UZ

KY

KY

FR

FR

DE

DE

EL

EL